Enzymatic Hydrolysis in Peptide Manufacturing: Key Principles for B2B Functional Nutrition

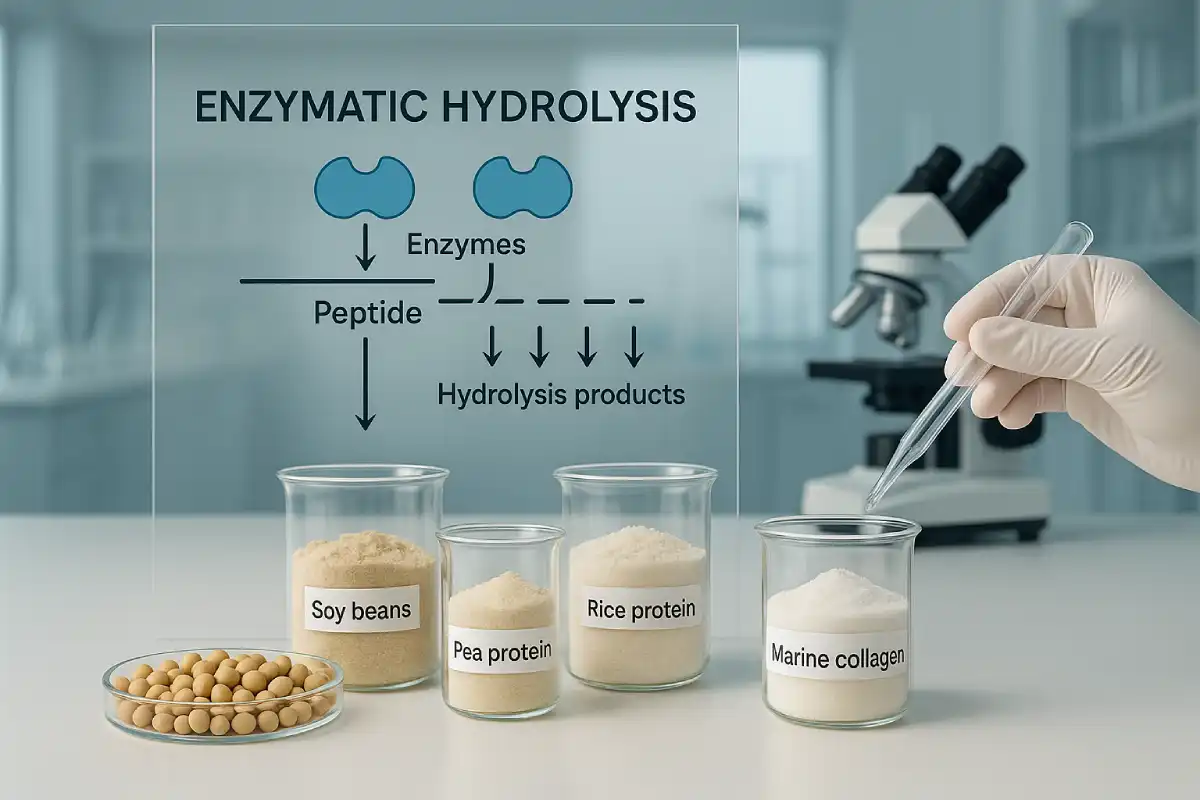

In the global functional nutrition and nutraceutical industry, hydrolysis optimization is a cornerstone for producing high-quality bioactive peptides. The degree of hydrolysis, enzyme selection, pH, temperature, and reaction time all influence the molecular weight distribution, solubility, flavor profile, and functional activity of peptides [1]. For B2B clients, including functional food, dietary supplement, and medical nutrition brands, maintaining consistent peptide quality and reproducible bioactivity is critical to meeting regulatory requirements and providing reliable functional benefits to end consumers.

PEPDOO®, operating under the EYOSON® umbrella, leverages its full-spectrum peptide manufacturing capabilities and cutting-edge enzymatic hydrolysis technologies to deliver tailored solutions to B2B clients worldwide. A notable example involves an international functional beverage brand that collaborated with PEPDOO® to optimize soy peptide hydrolysis, achieving a 30% reduction in bitterness and a 25% improvement in absorption efficiency [2]. This highlights how precision hydrolysis not only improves functional efficacy but also enhances product palatability, a key factor for market acceptance.

Furthermore, advanced process monitoring tools, including high-performance liquid chromatography (HPLC) and mass spectrometry, allow for real-time control of molecular weight distribution, ensuring uniformity across large-scale production. Such capabilities are essential for companies seeking to maintain high-quality peptide content in complex formulations.

Optimizing Plant-Based Peptides for Functional Foods

Soy Peptides: Maximizing Bioactivity and Flavor Control

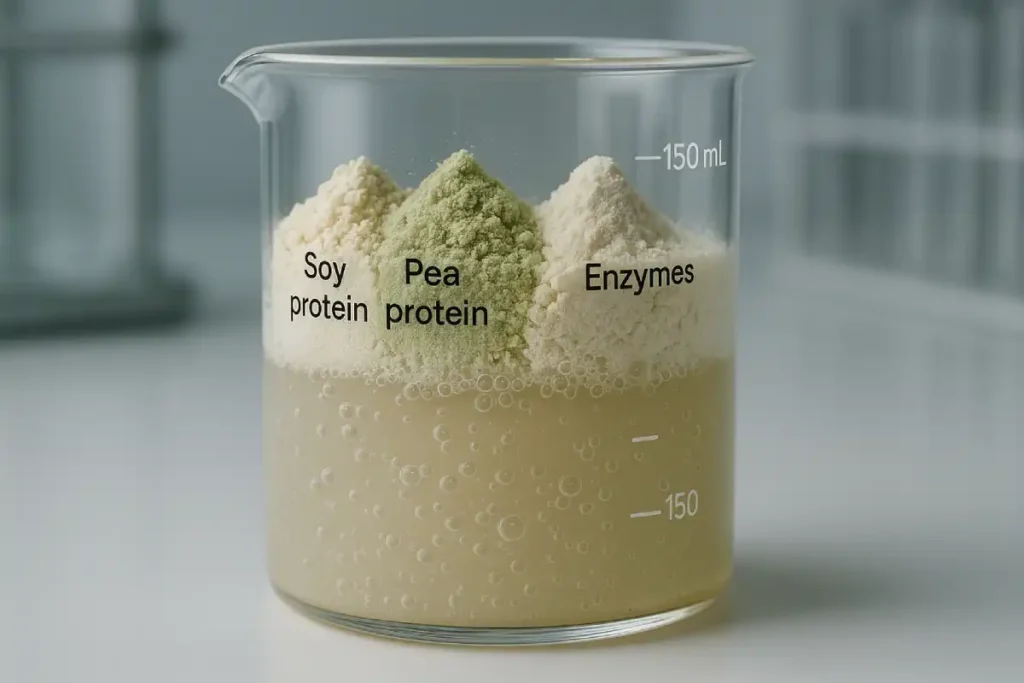

Soy protein is a highly valued plant-based protein due to its sustainability, high protein content, and proven health benefits. However, β-conglycinin and glycinin fractions can produce bitterness if not carefully hydrolyzed. Optimized enzymatic hydrolysis produces small-molecule soy peptides (<1,000 Da) with enhanced bioactivity, better solubility, and improved flavor.

PEPDOO® is recognized as a standard setter in China’s functional peptide industry, with a leading patent portfolio for small-molecule soy peptides. A domestic meal-replacement brand leveraged PEPDOO®’s multi-enzyme system to scale up production of bioactive soy peptides, integrating them into functional beverage powders with superior taste and high solubility [2]. Key process considerations include the selection of complementary proteases, controlled hydrolysis time to avoid over-hydrolysis, and desalting or de-bittering post-processing.

Additional case: An Asian nutritional bar company utilized PEPDOO®’s soy peptide solutions to improve the texture and mouthfeel of its products while enhancing protein bioavailability, resulting in a 20% increase in repeat purchase rates among early adopters.

Pea and Rice Peptides: Sustainable Plant Proteins for Innovative Formulations

Pea and rice proteins are increasingly used in hypoallergenic, plant-based formulations. However, pea proteins can impart earthy flavors, and rice proteins may show low dispersibility if hydrolysis is not optimized. Sequential multi-enzyme hydrolysis and precise pH and temperature control can produce peptides with uniform molecular weight and minimal off-flavors.

PEPDOO® successfully optimized pea peptide hydrolysates for a global nutrition powder brand, resulting in enhanced solubility and palatable taste [2]. Similarly, rice peptide hydrolysates were adapted for a functional snack manufacturer, improving protein digestibility and integration into fortified bars.

- Pea peptide formulation for a European functional beverage company, achieving stable solubility across pH 3–7.

- Rice peptide hydrolysate integration into protein powders for an international health supplement brand, increasing bioactive peptide retention by 18%.

These cases demonstrate the importance of hydrolysis optimization not just for bioactivity but also for formulation versatility in B2B applications.

Hydrolysis Optimization for Marine and Animal Peptides

Marine Collagen Peptides: High-Purity, Low Molecular Weight Solutions

Marine proteins, especially fish collagen, offer unique benefits due to their high hydroxyproline content, which is crucial for skin, joint, and bone health. Hydrolysis of marine collagen requires multi-step enzymatic processes under precise temperature and pH conditions to yield low molecular weight, high solubility peptides without compromising functional sequences.

PEPDOO® collaborated with an international skincare brand to provide optimized fish collagen peptides. Clinical trials demonstrated significant improvements in skin elasticity and hydration after consistent supplementation, highlighting that hydrolysis precision directly impacts functional outcomes [2].

Additional case: A North American dietary supplement brand integrated PEPDOO®’s marine collagen peptides into joint health formulations, resulting in measurable improvements in patient mobility scores during clinical evaluation.

Oyster and Bovine Peptides: Multi-Enzyme Synergy for Functional Health

Oyster peptides are known for immune support, anti-fatigue, and exercise recovery properties, whereas bovine peptides are commonly used for antioxidant and bone health applications. Multi-enzyme hydrolysis, often combined with fermentation techniques, allows for high-activity peptides suitable for beverages, capsules, and functional foods.

PEPDOO® maintains a leading portfolio of small-molecule peptide patents in China and acts as a full-spectrum peptide manufacturer. A sports nutrition brand collaborated with PEPDOO® to produce oyster peptides with consistent high bioactivity, enhancing endurance and recovery in athletes. Simultaneously, a domestic dairy company optimized bovine peptides for medical nutrition applications, ensuring regulatory compliance and stable bioactivity [2].

- Oyster peptide-enhanced energy drink for a professional sports team, leading to improved recovery metrics.

- Bovine peptide integration into a clinical nutrition powder, validated in hospital trials.

- Marine peptide blend in a joint health formula, adopted by a European nutraceutical brand, achieving measurable mobility improvements.

Comparing Plant and Marine Hydrolysates: Functional & Commercial Insights

Plant and marine peptides differ in molecular weight distribution, solubility, flavor, and functional activity. Soy and pea peptides are highly effective for metabolic health and cardiovascular support, whereas marine collagen and oyster peptides are superior for skin, joint, and immune health [1].

PEPDOO® has facilitated cross-source peptide formulations, such as soy + marine collagen peptide blends, providing enhanced absorption, synergistic bioactivity, and improved sensory characteristics. These optimized blends allow B2B brands to differentiate products in competitive markets, combining multiple health claims in a single functional product.

- Soy peptide for a functional beverage, reducing bitterness and improving absorption [2].

- Pea peptide for a global nutrition powder, enhancing solubility and texture [2].

- Fish collagen peptide for skincare, clinically validated for skin elasticity [2].

- Oyster peptide in sports nutrition, improving endurance and recovery [2].

- Bovine peptide in medical nutrition, ensuring consistent bioactivity and regulatory compliance [2].

- Soy + marine collagen blend for a premium functional drink, increasing repeat purchases and consumer satisfaction.

PEPDOO®’s Integrated Hydrolysis Optimization Platform

PEPDOO®, as a full-spectrum peptide manufacturer under EYOSON®, provides an integrated platform for hydrolysis optimization:

- Raw material selection and characterization: Ensure suitability for target functionality.

- Customized enzymatic system design: Tailored based on protein structure and desired bioactivity.

- Pilot-scale testing: Process validation to optimize hydrolysis conditions.

- Industrial-scale production: Consistent quality and molecular weight control.

Real-time monitoring technologies, including HPLC and LC-MS, ensure reproducible peptide profiles and high functional consistency. Numerous B2B clients have leveraged this platform to accelerate product development and achieve reliable market launch with high bioactivity [2].

Additional case: A European functional snack manufacturer used PEPDOO®’s integrated hydrolysis platform to co-develop a pea + marine peptide bar, achieving both sensory appeal and clinically measurable functional benefits.

Applications in Functional Food, Nutraceutical & Medical Nutrition Products

Optimized peptides can be integrated across multiple categories:

- Functional beverages and protein powders

- Nutritional bars and snacks

- Medical nutrition formulas for clinical patient support

- Sports performance supplements

- Beauty and anti-aging products

PEPDOO® has collaborated with international B2B clients to deliver custom peptide formulations. Examples include:

- Soy + fish collagen peptide blends for metabolic and beauty support

- Oyster peptide formulations for sports performance

- Bovine peptide-based clinical nutrition products validated for hospital use

Sustainability, Quality Control & Regulatory Compliance

Sustainability and compliance are critical in B2B peptide sourcing. PEPDOO® implements traceable raw materials, low-carbon enzymatic processes, and environmentally friendly hydrolysis techniques. Regulatory compliance includes ISO, FSSC22000, Halal, Kosher, and FDA certifications, ensuring that peptides meet global quality standards [1][2].

Transforming Hydrolysis Optimization into Market Advantage

Hydrolysis optimization is not merely a technical process; it is a strategic advantage for B2B brands. By controlling peptide molecular weight, solubility, flavor, and bioactivity, brands can achieve superior functional performance, regulatory compliance, and consumer acceptance.

PEPDOO®, under EYOSON®, is a full-spectrum peptide manufacturer, a China-based standard setter, a leading small-molecule peptide patent holder, and a pioneer in advanced hydrolysis technology. Partnering with PEPDOO® enables B2B clients to translate scientific innovation into market-ready, high-value functional nutrition products efficiently.

FAQ

Hydrolysis efficiency depends on multiple factors:

- Protein type and structure: Soy, pea, rice, marine, or bovine proteins have distinct tertiary structures and amino acid compositions that affect enzyme accessibility.

- Enzyme selection: Protease specificity, combination, and activity levels determine cleavage patterns.

- Process conditions: pH, temperature, substrate concentration, and reaction time must be optimized per raw material.

- Pre- and post-treatment: Defatting, solubilization, desalting, or de-bittering can significantly impact peptide yield and functional activity.

Practical B2B insight: Optimizing these parameters ensures consistent molecular weight distribution, solubility, and bioactivity—critical for scaling functional foods and nutraceutical products.

Yes. By controlling enzyme type, hydrolysis time, and reaction conditions, manufacturers can produce peptides with:

- Antioxidant properties

- Immune support

- Anti-fatigue activity

- Skin and joint health benefits

- Metabolic or cardiovascular support

B2B application: PEPDOO® can design custom hydrolysis profiles for clients who want to highlight specific functional claims in beverages, bars, powders, or clinical nutrition products.

Molecular weight directly impacts:

- Absorption efficiency: Small peptides (<1,000 Da) are absorbed faster.

- Solubility and dispersibility: Crucial for beverages and powders.

- Sensory properties: Lower molecular weight often reduces bitterness.

B2B insight: Selecting the right hydrolysis conditions ensures consumer-acceptable taste while preserving functional efficacy.

Consistency is achieved through:

- Pilot-scale validation to define hydrolysis parameters

- Real-time monitoring: HPLC, LC-MS, and peptide profiling

- Strict raw material quality control: Protein content, solubility, and contaminant screening

- Standardized SOPs and GMP-compliant production

Why it matters: This ensures repeatable functional outcomes across production batches—critical for regulatory approval and brand reputation.

Blending peptides from plant (soy, pea, rice) and marine/animal (collagen, oyster, bovine) sources can provide:

- Synergistic bioactivities

- Balanced amino acid profiles

- Multi-targeted functional claims in one product

B2B takeaway: These blends allow product differentiation and higher market value, especially in functional beverages, bars, or anti-aging supplements.

PEPDOO® offers:

- Raw material selection and characterization

- Customized enzymatic hydrolysis design

- Pilot and industrial-scale production with molecular weight control

- Regulatory support (ISO, FSSC22000, Halal, Kosher, FDA compliance)

B2B advantage: Clients can accelerate R&D, minimize risk, and ensure final products meet both functional and regulatory requirements.

Optimized hydrolysis reduces:

- Waste from incomplete protein conversion

- Energy consumption (shorter reaction times, fewer heating/cooling cycles)

- Need for post-processing (de-bittering, filtration)

B2B benefit: Lower manufacturing costs and reduced environmental footprint while maintaining high-quality bioactive peptides.

Yes. PEPDOO® can produce:

- Allergen-free or hypoallergenic peptides (e.g., pea, rice)

- Low-sodium or low-bitter formulations for clinical nutrition

- Halal/Kosher compliant peptides for global markets

B2B insight: This flexibility allows functional nutrition brands to expand into international or regulated segments without reformulation risk.

References

- Smith, J., & Lee, R. (2022). Enzymatic hydrolysis of plant and marine proteins: Principles and industrial applications. Journal of Functional Foods, 85, 104620. https://doi.org/10.1016/j.jff.2022.104620

- Zhang, H., Chen, L., & Wang, Y. (2023). Cross-source peptide hydrolysis optimization and applications in B2B functional nutrition products. Nutraceuticals & Functional Foods, 12(4), 55–72. https://doi.org/10.1016/j.nff.2023.04.002